搅拌装置的设计选型与搅拌作业目的紧密结合。在设计选型时首先要根据工艺对搅拌作业的目的和要求,确定搅拌器型式、电动机功率、搅拌速度,然后选择减速机、机架、搅拌轴、轴封等各部件。

根据搅拌介质物料的物理特性,按照工艺条件和搅拌目的,选择搅拌器型式。

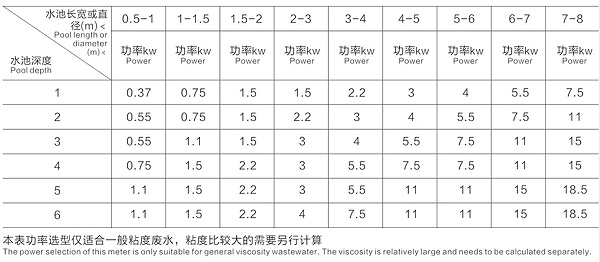

按照所确定的搅拌器型式及搅拌器在搅拌过程中所产生的流动状态,工艺对搅拌混合时间、沉降速度、分散度的控制要求确定电动机功率、搅拌速度、搅拌器直径。

按照电动机功率、搅拌转速及工艺条件,从减速机选型表中选择确定减速机机型。

根据容器或池体尺寸确定搅拌器层数: 1) T殳按照池体(容器)高度/池体直径(或长宽)比接近1:1,选择1层搅拌器;2) 当池体(容器)高度/池体直径(或长宽)比大于等于1.5:1,选择2层搅拌器;3) 当池体(容器)高度/池体直径(或长宽)比大于等于2.5:1,选择3层搅拌器

搅拌流量、电机率的计算,这是非常重要的一步:一般是根据搅拌强度的需要来确定,采用计算软件进行计算,具体计算时需输入粘度值、密度、桨叶层数、转速等参数。

液体搅拌机封密型式的选择:1) 一般情况下,不考虑设置密封装置;2) 有密封要求,但密封要求不太高的场合,优先选择四氟盘根的填料箱密封;3) 严格密封要求的,可采用磁力传动静密封结构,即选用磁力传动(驱动)搅拌机。

Choosing mixer models according to physical properties of mixing material, tech no logical conditi ons and mixing purposes.

Determining motor power, mixing speeds and mixer diameters according to determined mixer models, flow patterns during mixing and technical control requirements of mixing time, sedimentation velocity and dispersity.

Selecting determined speed reducer models from the speed reducer model table according to motor power, mixing speeds and technological conditions.

Determine the number of agitator layers according to the size of the container or pool:1)、Gen erally, accordi ng to the height of the pool body (con tainer) / the diameter of the pool body (or length and width) is close to 1:1, select a layer of mixer; 2)、When the cell body (container) height / cell body diameter (or length to width) ratio is greater than or equal to 1.5:1, select a 2-layer mixer;3)、When the cell body (container) height / cell body diameter (or length to width) ratio is greater than or equal to 2.5:1, select a 3-layer mixer

Calculation of mixing flow and motor power is a very important step:Generall, it is determined according to the need of strring intensity,and calculation software is used for calculation. In the specific calculation, parameters such as viscosity value, density, number of blade layers, and rotation speed are input.

Selection of Seal Models of L iquid Mixers:1)、Under normal circumstances, it is not considered to set the sealing device;2)、Where there is sealing requirement, but the sealing requirements are not too high, the packing box sealing of PTFE packing is preferred;3) For the strict sealing requirements, the magnetic transmission static sealing structure can be used, that is, the magnetic drive (drive) mixer is selected.

结构简单,占地比较小,安装方便。

适用于低粘度液体的混合、均匀、调和、溶解、传热或结晶。

The structure is simple, the footprint is relatively small, and the installation is convenient.

Suitable for mixing, homogenizing, blending, dissolving, heat transfer or crystallization of low viscosity liquids.

广泛应用于电镀产业园、化工厂、光伏厂、冶炼厂、市政污水处理厂、制药厂等各行各业,把高效传动搅拌的知识和水利及流态经验创新结合起来,让处理的每个工段和每一滴液体实现较佳的运行性能,致力于为客户创造更大价值而不懈努力!